When you visit any website, it may store or retrieve information on your browser, mostly in the form of cookies. This information might be about you, your preferences or your device and is mostly used to make the site work as you expect it to. The information does not usually directly identify you, but it can give you a more personalized web experience. Because we respect your right to privacy, you can choose not to allow some types of cookies. Click on the different category headings to find out more and change our default settings. However, blocking some types of cookies may impact your experience of the site and the services we are able to offer. Privacy Policy & Cookie Policy

MAX developed the 500 psi PowerLiteⓇ system and introduced to the Japan market in 1994.

In 2006, MAX started selling the PowerLiteⓇ system in North America and has since been expanding the market of next-generation fastening systems. So why high pressure?

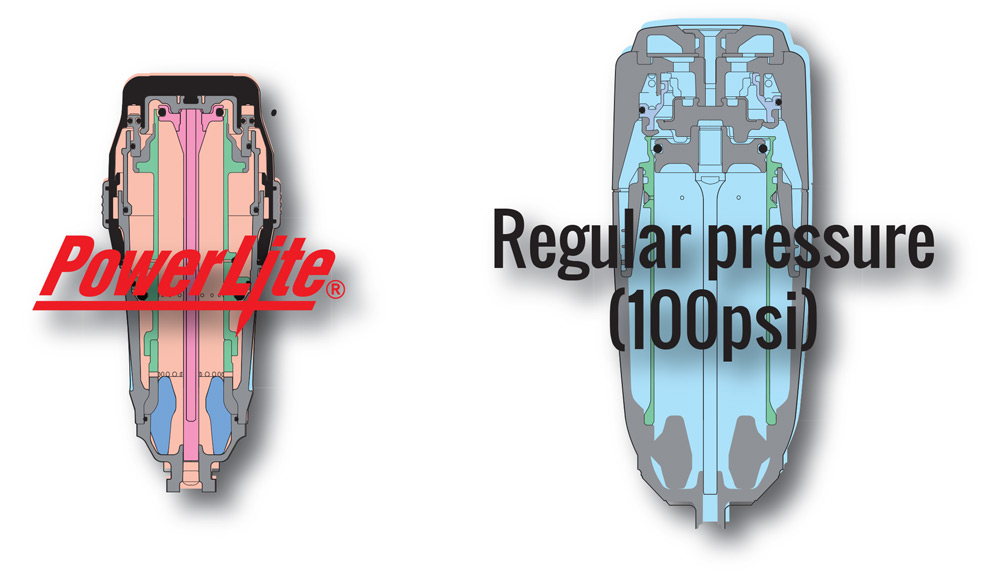

It’s simple. Higher air pressure brings higher driving power. The PowerLiteⓇ tools are extremely powerful yet their size is 40% smaller and tool weight is 30% lighter than coventional regular pressure tools. With the PowerLiteⓇ system you can fasten not only engineered woods but also wood to concrete, wood to I-beam and steel to concrete.

BENEFIT

PowerLiteⓇ compressor compress the air up to 500 psi. The high pressure system enable the PowerLiteⓇ tools to be not only compact and lightweight but also extremely powerful.

Since 150 psi- 320 psi compressed air goes into small body, they don’t require much air than a conventional regular pressure tools to shoot fasteners. Of course, high pressure air brings higher driving power than a conventional regular pressure tools.

Overall, PowerLiteⓇ 500 psi high pressure system works with every fastening applications in your job site such as steel, concrete and engineered wood.

APPLICATIONS